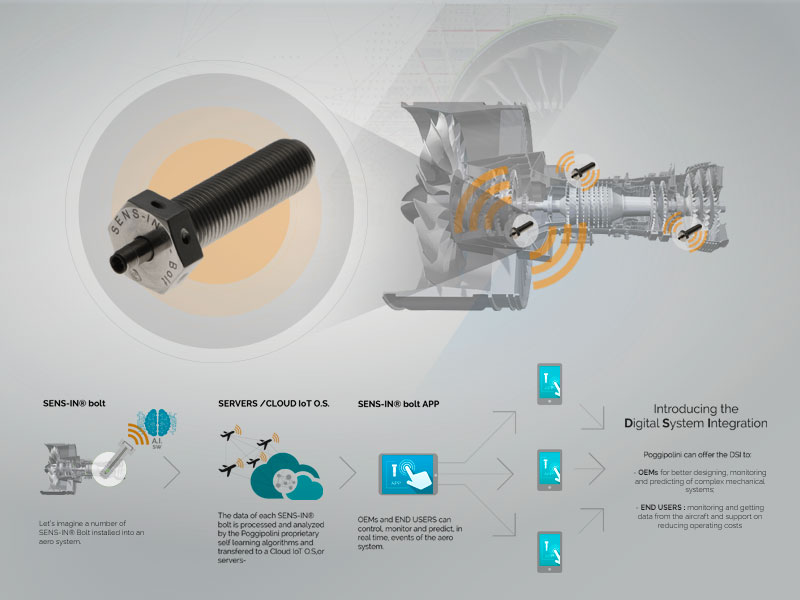

Mechadigital: Sens-in® Bolt An intuition, a challenge that has become a revolutionary product: the Sens-in® Bolt, the smart bolt is born.

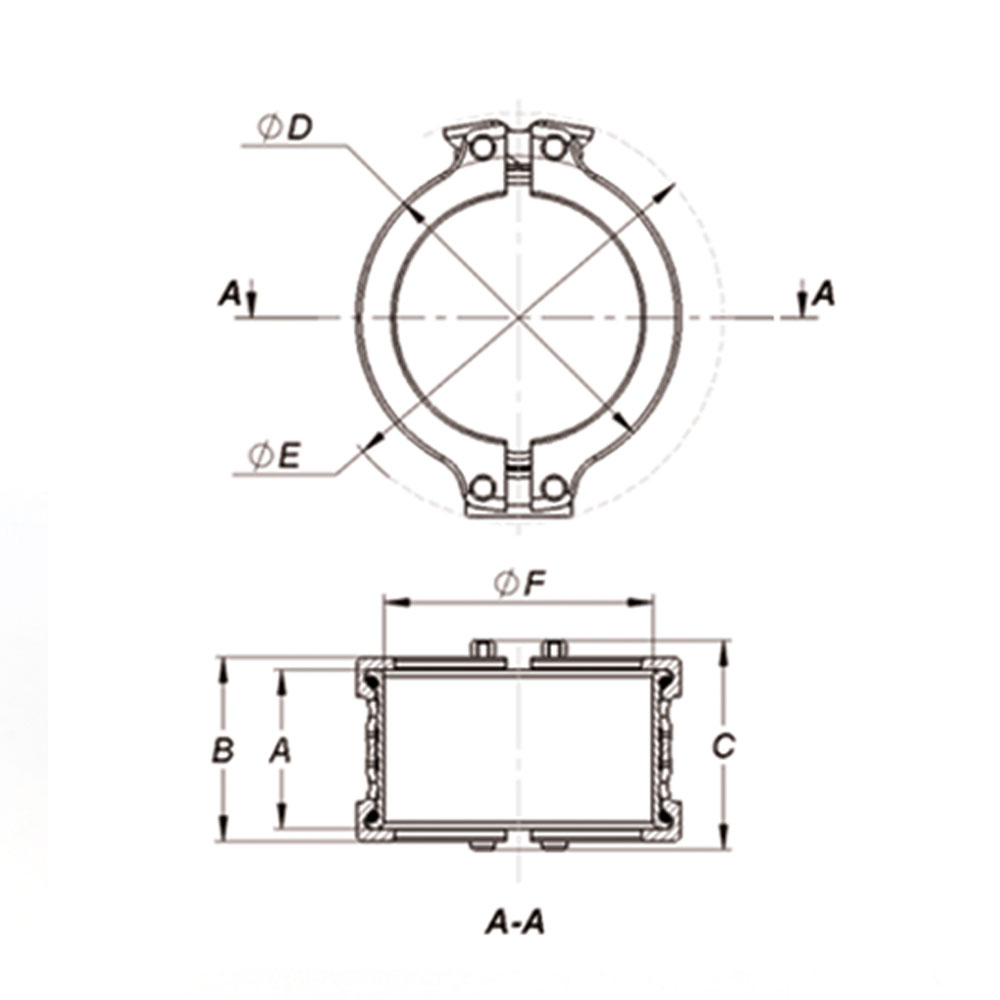

The objective is to combine electronic components and sensors with mechanical engineering in an innovative product that can perform several functions simultaneously, thereby optimising weight and space in order to become a new solution for monitoring complex systems. The Sens-in® was patented as a result of the collaboration between Poggipolini, a leader in the design and manufacture of fasteners for the aerospace and Motorsports industries, with the support of Research Centres and cutting-edge European Universities, after three years of work, studies and prototyping, according to different physical quantities intercepted by fasteners.

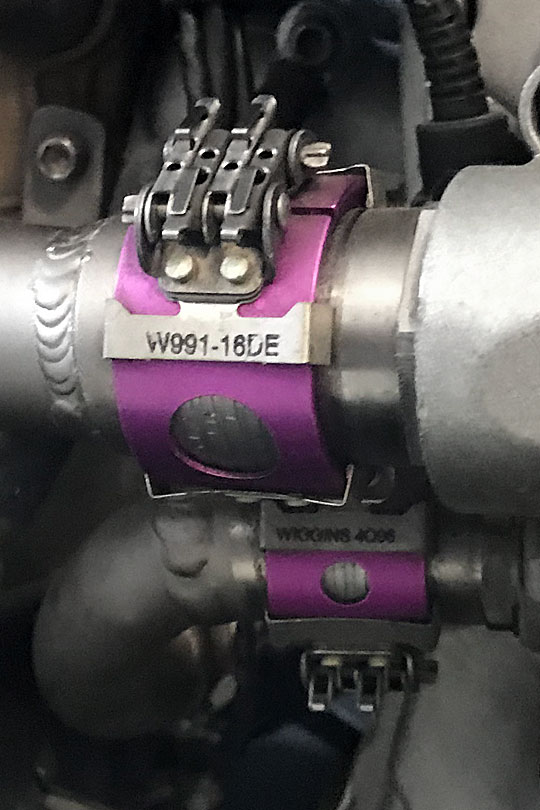

The first "intelligent" bolt integrating sensitive elements for measuring temperatures, thermal flows and other physical parameters (patent pending).

.jpg)