Weight reduction

We offer weight reduction solutions by replacing steel screws with titanium screws, including for high-volume production.

Not only screws:

- bulkheads and bodywork panels, engine and interior in titanium, both aesthetic and structural;

- mechanical and/or aesthetic accessories worked mechanically, both in titanium and carbon;

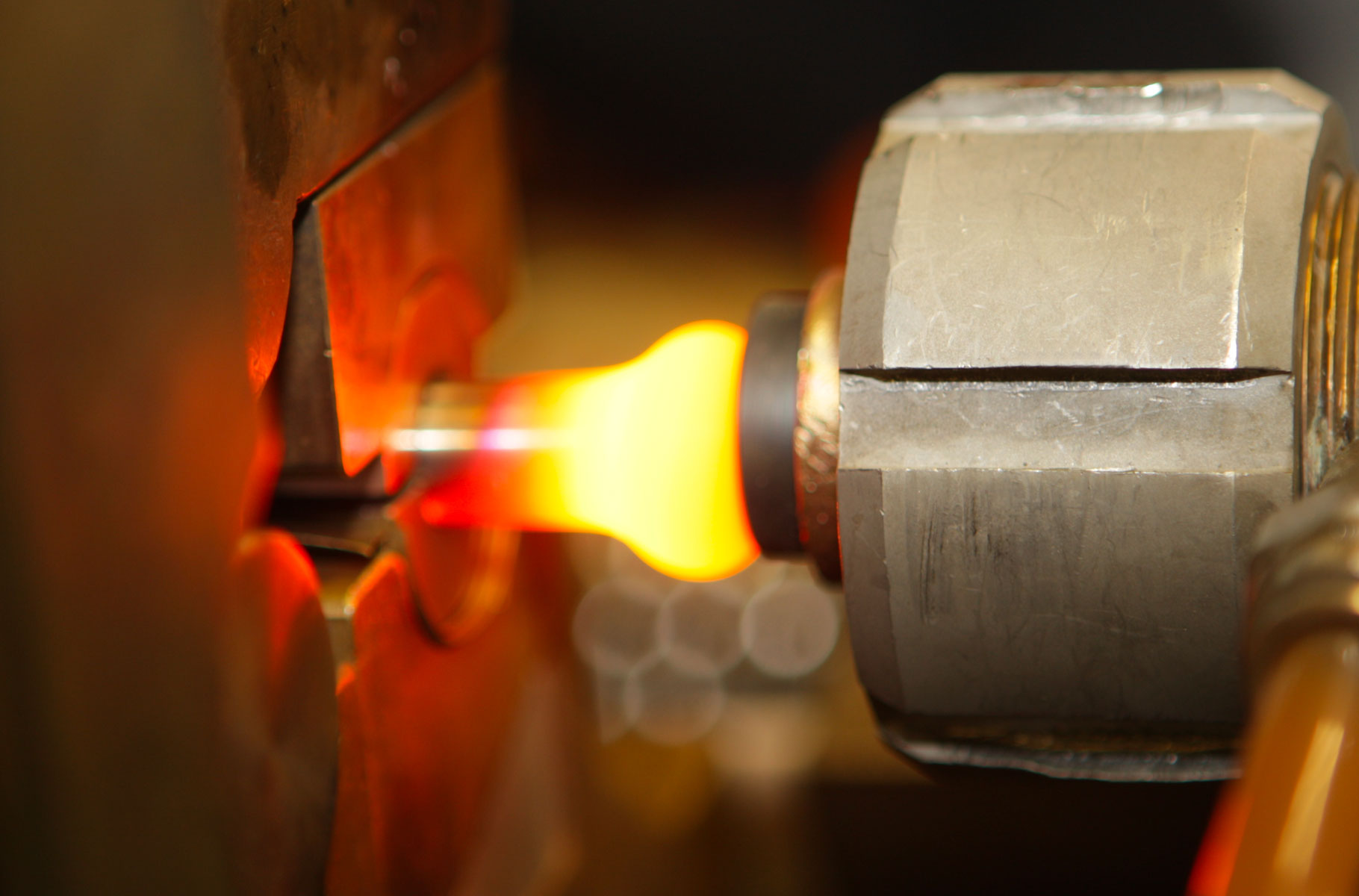

- titanium welded structures, such as roll bars and frames;

- Additive Manufacturing